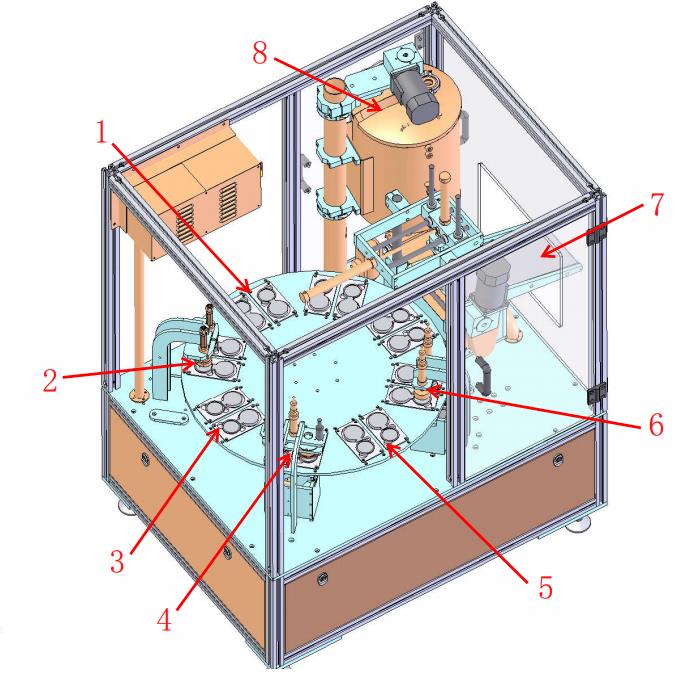

SLQD-A Air cushion BB cream machine

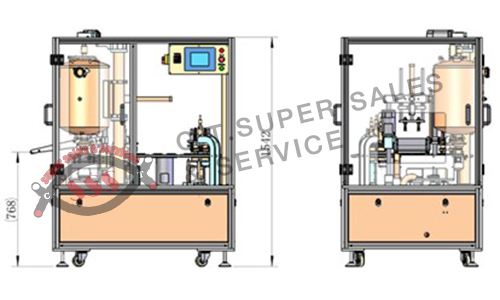

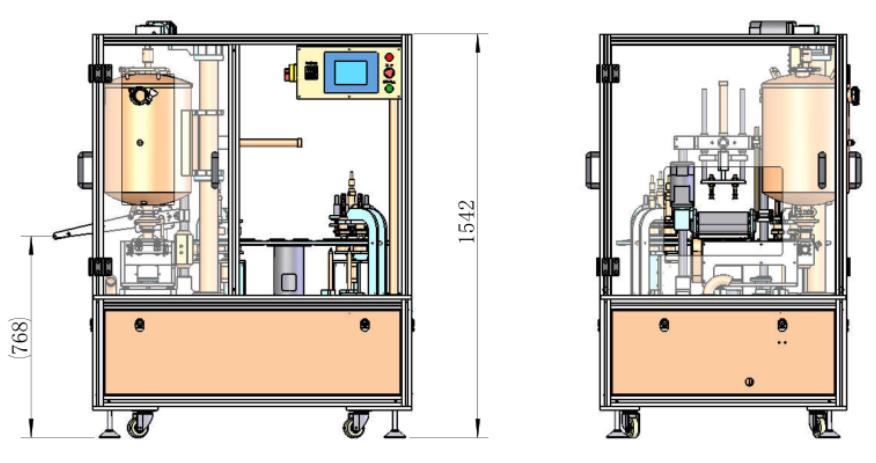

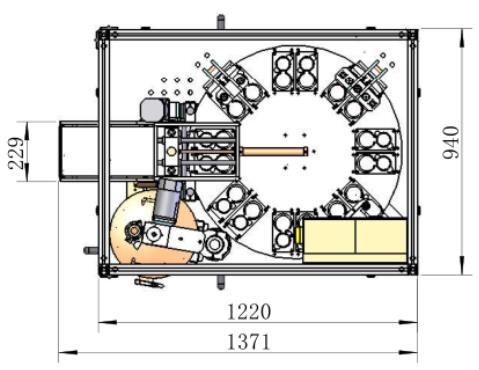

1. The overall structure of the machine

2. Function description of each part:

1. Put bottle station

2. Filling station

3. Cotton discharge station

4. Press cotton station

5. Put the inner ring station

6. Pressure inner ring station

7. Finished products sent

8. Bucket

3. Working process

Manual air cushion box - Hand sponging - Automatic filling

Put the inner ring manually - Automatic pressure inner ring

Finished product output

4. Technical parameters and spare parts configuration

| Molde | SLQDBB-A | Name | Brand |

| Capacity | 1800~2500PCS/h | PLC | Inovance |

| Mold specifications: | Customized | Touch screen | Inovance |

| Power: | 220VAC 50Hz 1ph2KW | Servo motor | Inovance |

| Compressed Air | 0.6Mpa. 150L/Min | Pneumatic component | AIRTAC |

| Machine size | L1380*W940*H1782 | Metering system | Precision piston pump |

5. Technical characteristics:

1. Manual air cushion box, manual sponge, automatic filling, manual inner ring, automatic pressure inner ring, grab bottle to the production line

2. The use of servo motor to drive the piston pump, high filling accuracy, the barrel with heating function, optional batching cylinder level detection system

3. PLC+ LCD touch screen control operation, can easily set equipment parameters on the touch screen, output and error information is clear and intuitive

4. Electrical and pneumatic components are selected from international well-known brands.

เครื่องบรรจุแนวตั้ง

เครื่องบรรจุแนวตั้ง